Regular maintenance can improve efficiencies and reduce overall maintenance costs and downtime

Glass manufacturers are producing more than ever to meet the needs of various applications. Today’s glass manufacturers fulfill the consumer demands of everything from windows to smartphone screens, storage jars, rotary blades in wind turbines, and more.

While the demand for these products increases, so has the costs for the manufacturing plants that use industrial and glass furnaces.

Industrial and glass furnaces that run their operations on natural gas have seen those natural gas prices soar to their highest levels since 2008. These increased manufacturing costs mean that the energy costs alone account for 40% of their total costs, whereas before 2020, the total energy costs were only about 14%.

While natural gas prices are expected to remain high throughout 2022, industrial and glass furnaces can optimize their operations with a proactive strategy of regular maintenance. Finding and eliminating problems before they occur will lead to less downtime and increased cost savings throughout the year.

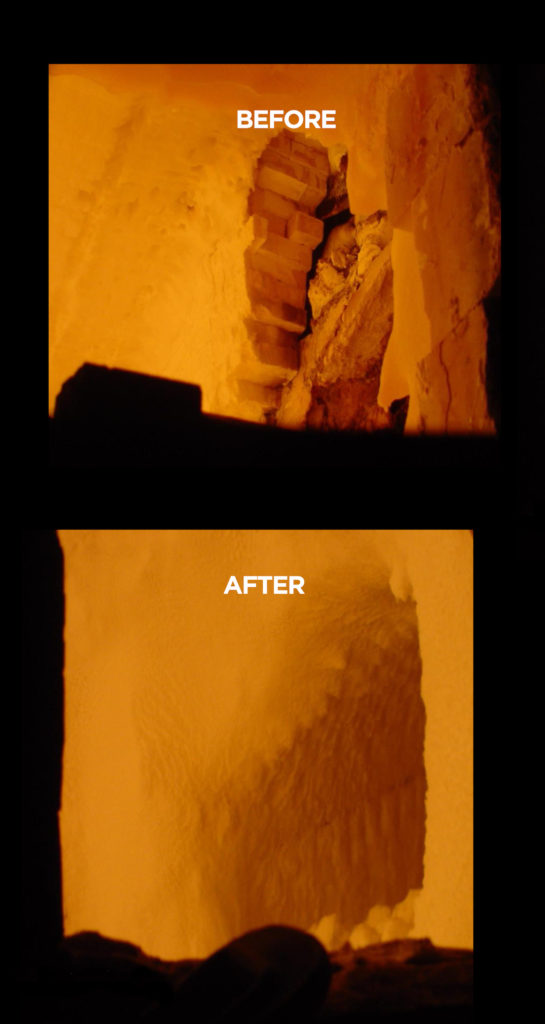

Fuse Tech offers our customers a range of ceramic solutions for cold and hot face weld repairs and maintenance, depending on the location of the damaged area of the furnace. Our complete line of proprietary and patented ceramic weld materials are available for applications such as the repair of cement kiln nose rings, repair of glass furnaces, repair of coke oven jambs, and the repair of high temperature furnaces and coke ovens.

A proactive maintenance strategy starts with an audit, which will establish the current state of the melter and associated systems to identify any maintenance or corrective work required to sustain an efficient operation. We can provide you with a complete picture of the current state of your industrial or glass furnace and highlight any necessary repairs or maintenance for optimal performance of the furnace or associated systems.

Fuse Tech is focused on fixing your problems for the long term and avoiding the possibility of worsening undesirable conditions.

Contact us today to start a maintenance plan for your facility and avoid higher-cost emergency situations.